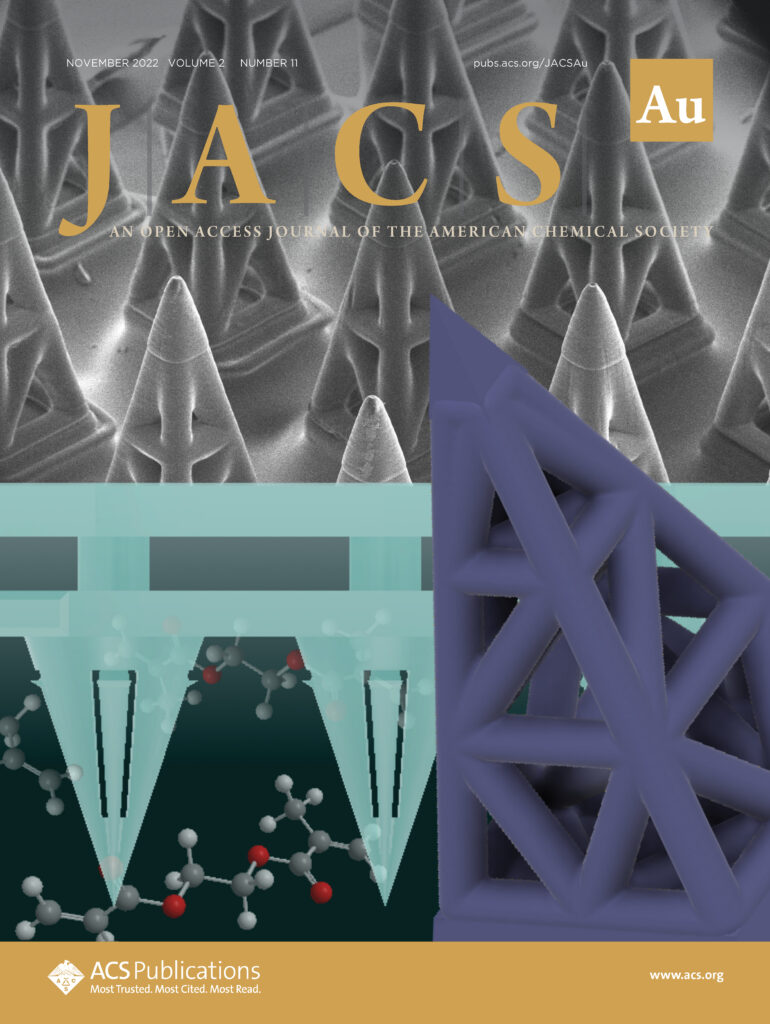

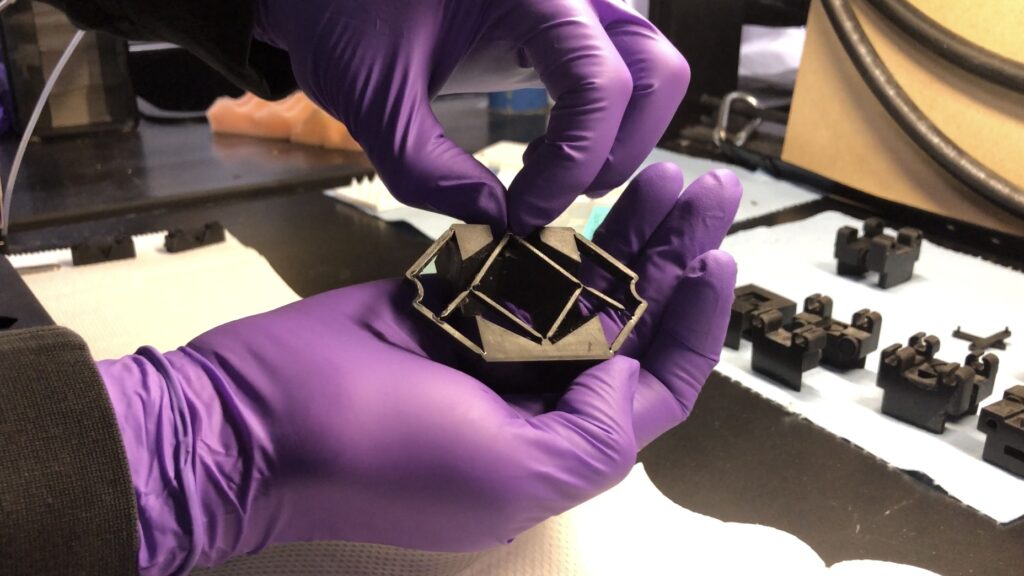

Biomimetic Microneedle Design and Prototyping

DeSimone Lab, 2022

Overview: Lab wide design project to create the best microneedle design for vaccination and interstitial fluid monitoring.

The basic concept: microneedles have the potential to deliver vaccines and monitor health at a scale that has never before been attempted – but only if their design can be made safe, functional, and easy to use.

The project: Designed, printed, and tested porcupine quill-inspired microneedles that reversibly lock into the skin. Lead to contributing author publication and patent (pending) on biomimetic microneedle design.

The main challenge: Incorporating movable parts into a 3D print that are strong and flexible at <100 um is a design, material, and manufacturing challenge with significant engineering tradeoffs.

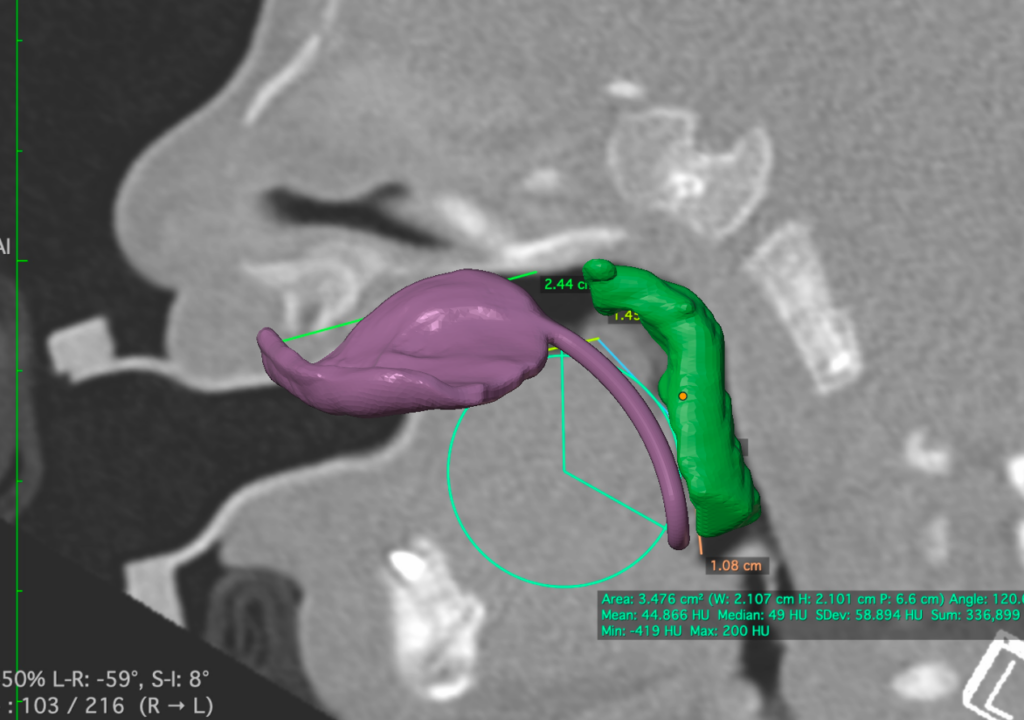

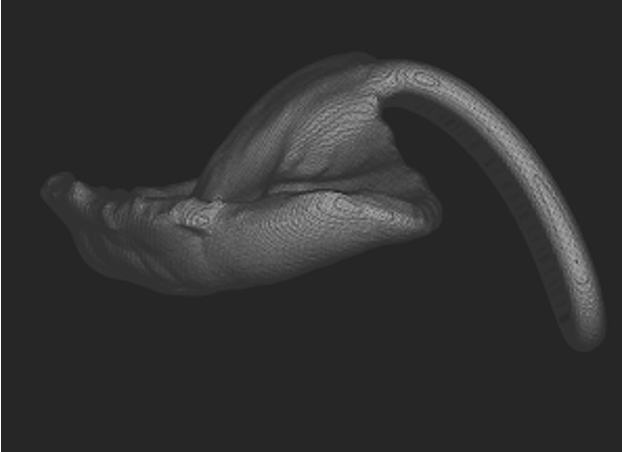

Cleft and Oral Airway Plate Digitization

DeSimone Lab, 2020 – 2021

Overview: Collaboration between the DeSimone Lab and Dr. Hyeran Choo at Stanford Hospital to digitize a 14 hour oral device manufacturing process into a 2 hour 3D modeling + printing workflow.

The basic concept: For infants with Pierre-Robin Sequence and Cleft Palate, using an Cleft Palate + Oral Airway Plate (CPP, OAP) reduces the number of surgeries required. But the plates are not scalable at 14 hours/device.

The project: design and manufacture bespoke devices using digital scans that are 100% patient customized.

The main challenge: going from 0 to 1 (copying the device) was doable (see images). But creating an automated tool that is intuitive for a clinician was a much larger challenge.

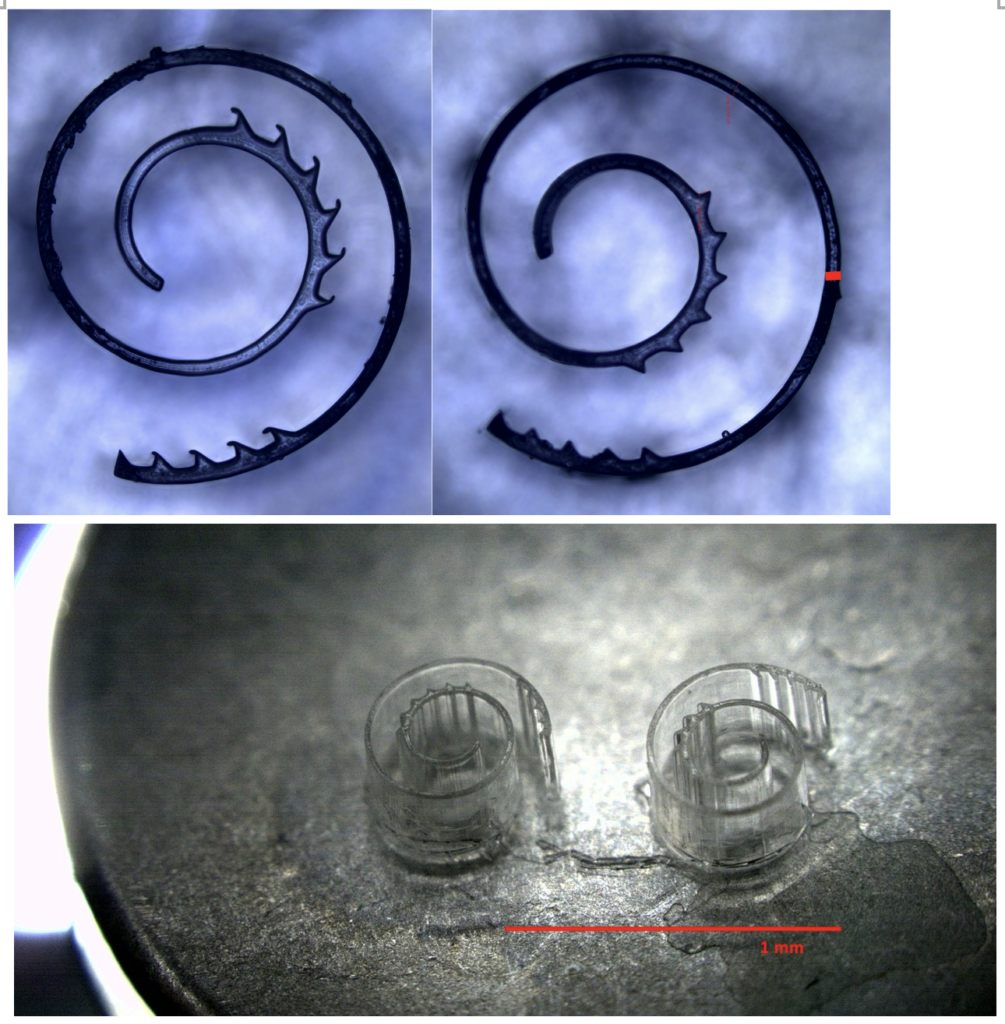

Bioresorbable Stent Design

DeSimone Lab, 2022 – 2023

Overview: Collaboration between the DeSimone, Thakor (Stanford) and Becker (Duke) labs to use 3D-printable, degradable materials in stent design.

The basic concept: Stents blow open arteries and hold them, but after the arteries heal, the stent can cause complications.

The project: designed and printed stents that degrade, and lock in an open position.

The main challenge: degradable stent materials are soft and rubbery, unlike metal stents. Novel designs are needed to increase open rigidity.

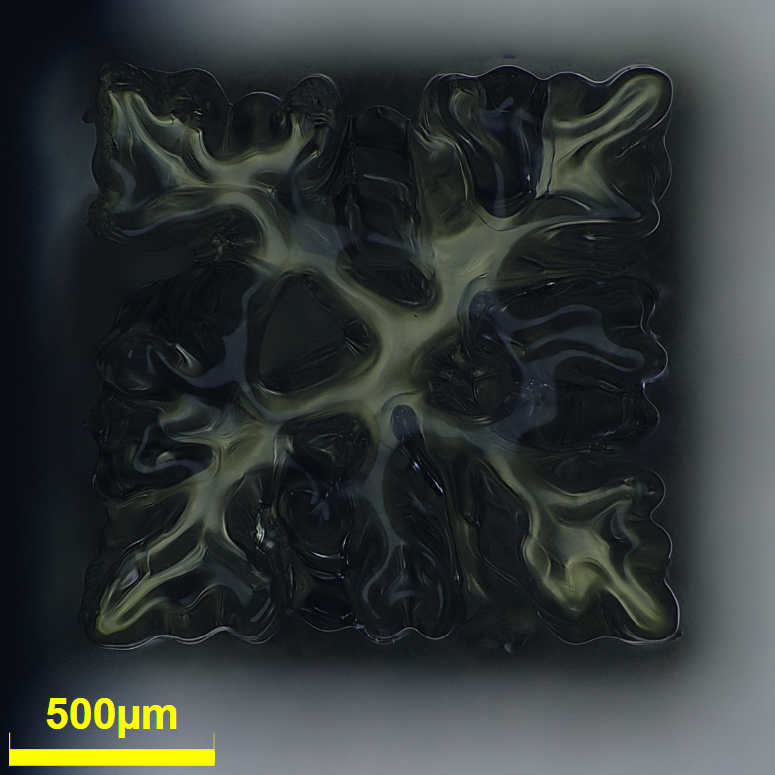

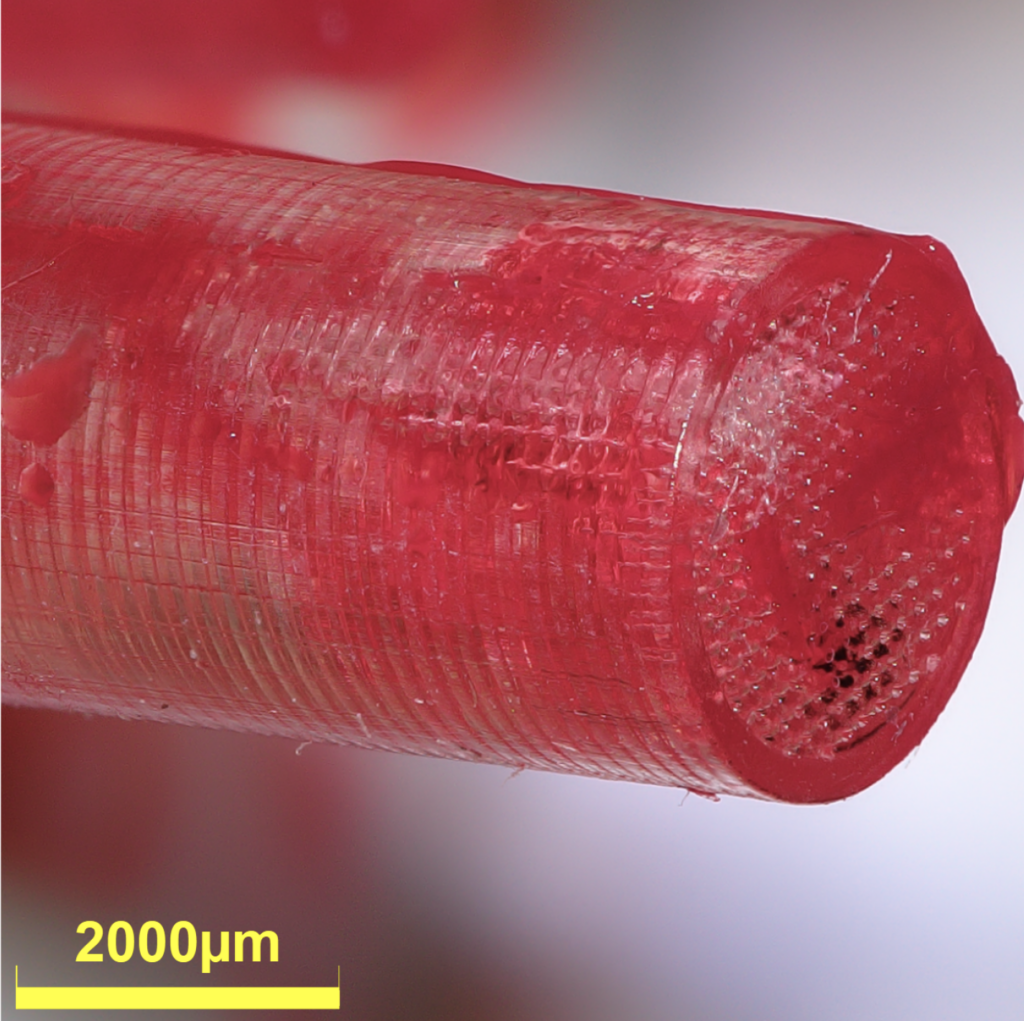

Perfusion Columns for Filtration

DeSimone Lab, 2022 – 2023

Overview: Perfusion columns are used to filter blood of bacteria and toxins, but are expensive and complex to manufacture. 3D printing offers a simple drop in to get perfect packing efficiency.

The basic concept: 3D printers are designed to create the perfect repeating structure needed for perfusion columns.

The project: designed and perfused many different packed columns, parameters, materials, washing conditions.

The main challenge: light based printers have a gel point – expose light, get long polymer, make solid. These reactions run beyond the light exposure, so micro voids seal shut if not flushed immediately.

Compliant Hinges

DeSimone Lab, 2022

Overview: 3D printed hinge research with Jo-Ann Efobi and Dr. DeSimone. Quantifying macro and micro performance of 3D printed hinges.

The basic concept: 3D printed geometries can be more complex than any other type of process, but are often locked in their printed form. How can these geometries be made to move and respond to applied forces?

The project: designed and tested the fatigue performance of different materials as print in place living hinges. Built a custom cycler.

The main challenge: Almost all 3D printed materials are poor hinges, and detecting microscale cycling failure requires a lot of creativity.

Longitudinal Ant Survey and Dissection

Gordon Lab, Summer 2019

Overview: studying the behavior of desert ants in remote Arizona

The basic concept: Dr. Gordon has been tracking the same ant colonies for 30 years – tracking colonies, changing environmental conditions, and behavior.

The project: count a lot of ants. Dissect a few poor souls.

The main challenge: I hate dissecting animals. Also, I almost stepped on six rattlesnakes.

Vine Robot Pressure Vessel

Okamura Lab, Spring 2024

Overview: Help a team of PhD students design and test a higher pressure version of their vine robot.

The basic concept: vine robots (steerable, snake-like pressure tubes) have the potential to help with search and rescue and soft handling.

The project: design a pressure vessel, novel window quick release, and test sealing and gaskets.

The main challenge: User requirements (no welding, stock parts only, must open in <60 seconds) often meant that novel solutions needed to be designed and tested. Novel pressure vessels need a lot of vetting to be safe, and this was only a 10 week project.

Family bonding

Shea Lab, 1999 – Current

I am lucky to help my dad (Dr. Kevin Shea, orthopedic surgeon) prototype and test medical devices. We are currently working on suture locks and better fracture setting tools. Not real research experience… but I get bonus time interviewing experts and designing for them.